Fiberglass Pipe For Industry with Over 30 Years of Experience

Introducing IntegraLine Fiberglass Pipe – FRP (Fiberglass Reinforced Plastic) Pipe

After years of serving corrosion-related industries, Fibrex noticed there seemed to be no easy approach to selecting and designing fiberglass reinforced plastic (FRP) pipe (also known as GRP pipes). Most plants have worked with fabricators and engineers to custom design all fiberglass pipe (FRP) equipment. Yet there is considerable cost and effort to custom design fiberglass pipe or a fiberglass pipe system and it is not always necessary. Fibrex has found there are many applications where a standard FRP pipe product will meet all of the requirements. That’s why Fibrex has developed a standard pipe product line called IntegraLine.

After years of serving corrosion-related industries, Fibrex noticed there seemed to be no easy approach to selecting and designing fiberglass reinforced plastic (FRP) pipe (also known as GRP pipes). Most plants have worked with fabricators and engineers to custom design all fiberglass pipe (FRP) equipment. Yet there is considerable cost and effort to custom design fiberglass pipe or a fiberglass pipe system and it is not always necessary. Fibrex has found there are many applications where a standard FRP pipe product will meet all of the requirements. That’s why Fibrex has developed a standard pipe product line called IntegraLine.

IntegraLine is a standard production fiberglass pipe with custom corrosion resistance. Simple to specify and select, this fiberglass pipe is ideal for new system installation or replacement of existing pipe. IntegraLine pipe will meet many of the applications and life-span requirements at your plant or facility.

For special design requirements, Fibrex also offers custom fiberglass pipe solutions. Custom fiberglass pipe solutions may require thicker corrosion or abrasion barriers with different resins. Also, heavier structural laminates and special glass reinforcements are available to meet installation and temperature requirements. Fibrex can provide design recommendations for a proposed installation.

And because Fibrex understands the industries we serve, Fibrex products are designed to meet the most demanding and specialized conditions at each site. In standard pipe, custom pipe, special header systems, duct or stacks, Fibrex delivers long-term corrosion solutions and absolute maximum product life. We call this “performance-based manufacturing.”

- cost savings

- faster production and quicker delivery

- fast and easy fiberglass pipe selection

Corrosion Resistance

IntegraLine fiberglass pipe ( fiberglass reinforced plastic pip – FRP) is designed to be “user friendly.” The resin, glass reinforcement

materials and composite construction were selected to provide consistent corrosion resistance for the majority

of chemical applications for which FRP pipe is considered appropriate. There remain certain extreme chemical services

for which special construction and alternative resins should be considered. Fibrex can advise if this is required for

your application.

Weather Resistance

IntegraLine pipe utilizes a heavily resinated exterior coat containing an ultraviolet stabilizer to impart long term

resistance to the effects of sunlight and other weathering elements. Should pipe become weathered after many years in

particularly severe environments, the exterior can be sanded and resin coated or painted.

Color

Pigmented exterior gel coats are not used on IntegraLine pipe in order to take advantage of the natural translucency

of FRP. Visual inspection of the pipe, both new and after years of service, is more reliable with a “natural” laminate.

Additionally, the liquid contents can often be observed in the pipeline… sometimes a process control advantage.

When special color coding is required, however, this can be provided at a nominal added cost and slightly longer

delivery time.

Durability

The high tensile elongation properties of the vinyl ester resins utilized in IntegraLine pipe impart a superior

The high tensile elongation properties of the vinyl ester resins utilized in IntegraLine pipe impart a superior

toughness to the pipe enabling it to resist cracking and crazing of the resin when subjected to heavy design loads.

In addition to high fatigue resistance, this toughness also provides a safety factor against impact damage during

shipping and installation.

Resin

IntegraLine pipe is manufactured with a premium vinyl ester resin as the standard production resin. Other vinyl ester resins specified by the customer are available, however delivery lead times will generally be longer. Epoxy vinyl ester resins are

premium corrosion resistant resins. At both room and elevated temperatures, these resins offer resistance to a broad range of acids, alkalis, bleaches and solvents making them the appropriate choice of resins in many chemical processing industry applications. These

resins, when properly formulated and cured, comply with FDA regulation 21 CFR 177.2420 covering materials intended

for repeated use in contact with food. Specific chemical resistance information can be found in the Chemical Resistance

and Engineering Guides, available from FIBREX or directly from the resin manufacturers.

Reinforcement Materials

A “C” glass (chemical grade) veil is provided on all surfaces exposed to corrosive media. Fiberglass used in

all subsequent layers of the laminate has excellent electrical resistivity, high tensile strength, moderate thermal

conductivity and is noncombustible. The basic types of fiberglass materials used; mat, woven roving and continuous

strand, are selected for their physical properties, manufacturing characteristics and the chemical resistance of the

laminate resulting from their use.

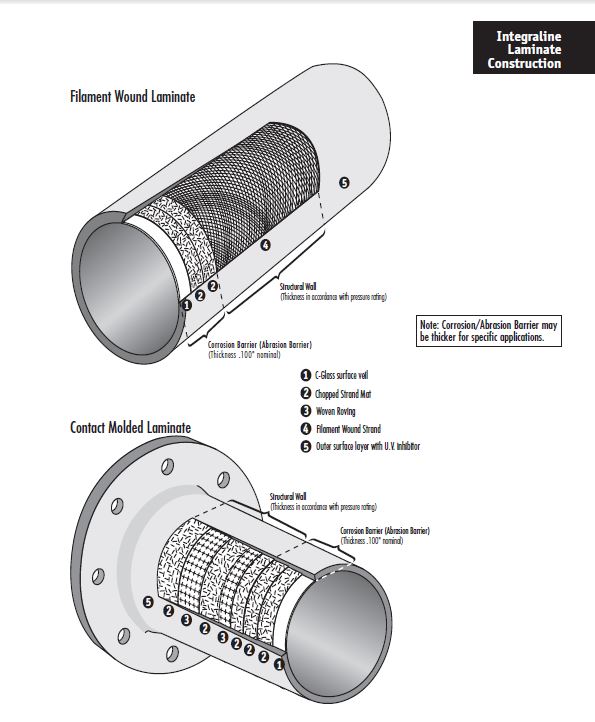

Corrosion Barrier

The corrosion barrier of IntegraLine pipe is nominally 100 mils thick and is comprised of 70% to 80% resin. This

highly resinated laminate is reinforced by one layer of “C” glass veil followed by two layers of randomly oriented fiber

strand mat.

Structural Laminate

Straight Pipe

IntegraLine pipe is manufactured by the filament winding process utilizing continuous fiberglass strand wound in a

helical pattern at a nominal 55 degree wind angle to produce an optimum combination of hoop and axial properties

for most typical applications. The high glass content resulting from the filament winding process imparts excellent

strength characteristics to the laminate providing superior protective structural backup to the resin rich corrosion barrier.

Fittings

IntegraLine pipe fittings are manufactured utilizing a highly efficient contact-molded laminate consisting of

alternating layers of glass fiber strand mat and bi-directional woven glass roving. The high glass content resulting

from the specific laminating process used for IntegraLine pipe fittings permits the wall thickness of this hand-layup

process to closely approximate the wall thickness of filament wound straight pipe in equivalent pressure rated classes.

Fiberglass Pipe Laminate Construction

Fiberglass Pipe Design and Selection, System Design, Field Installation:

Click Here to Print the Fiberglass Pipe Manual for Chemical Plants

Click Here to Print the Fiberglass Pipe Manual for Power Plants

Click Here to Learn More About Fiberglass Pipe IntegraHeader – The Long-Term Chlorine Header Solution