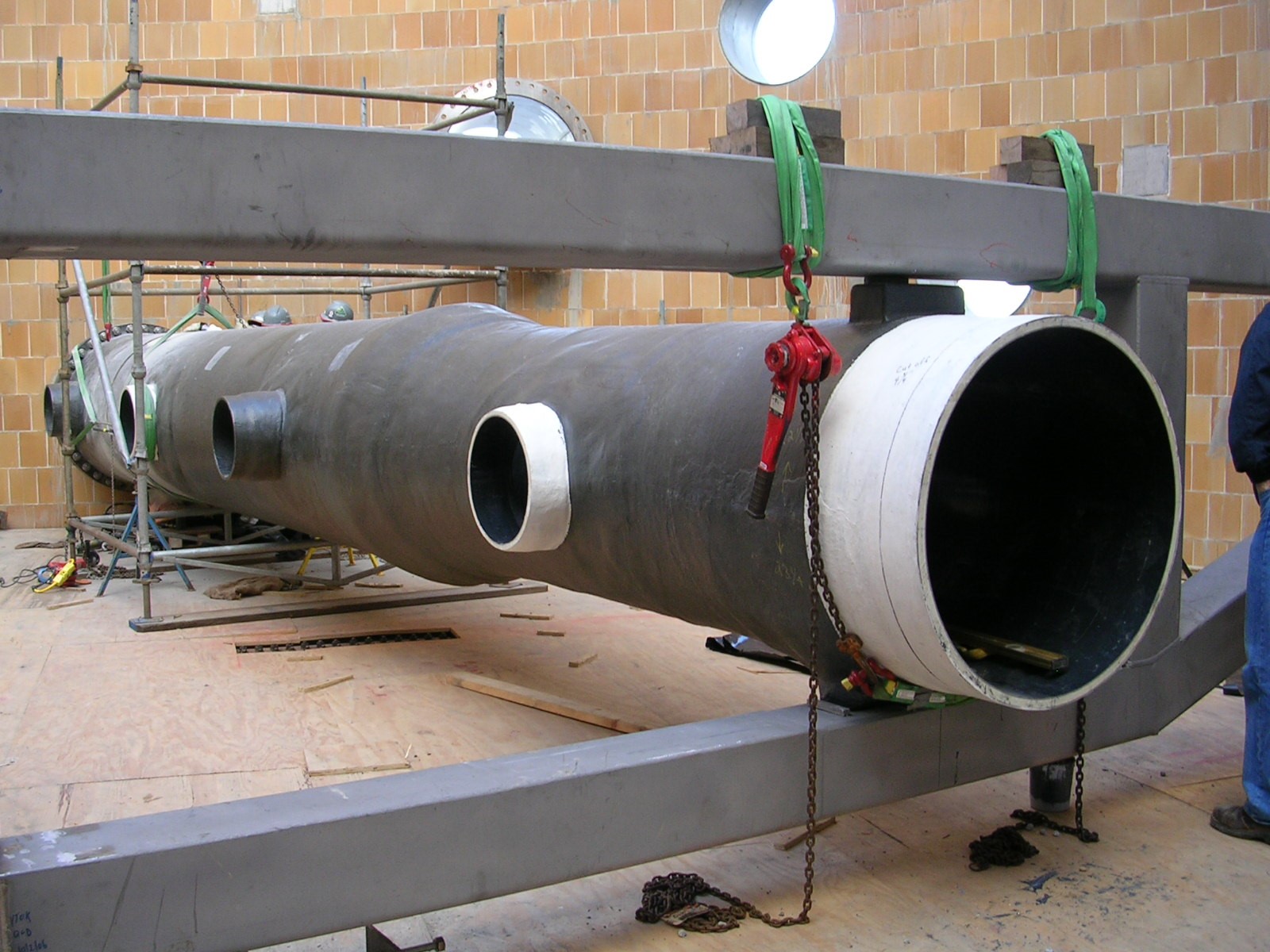

Project: FGD SPRAY HEADERS

Client: U.S. coal-fired power plants

General Scope: A total of fifteen spray headers for three identical absorbers and six spray headers for a larger absorber.

Engineering/Procurement: Babcock Power Environmental Inc.

Resin & Laminate Construction: Hetron 922 vinyl ester was selected for the service. The headers had an interior abrasion-resistant liner of 0.150” and an exterior AR liner of 0.200”. The structural laminate in between was pigmented a contrasting color to allow visual inspection of the liner for any eventual “show through”.

Production Facts: Client specifications required the header system to be designed for maintenance platform loads. For this reason, all pipe was hand lay-up construction to increase axial strength. Finite Element Analysis was used for the design.

Special Project Note: Client specifications required a smooth-turn connection at all branch (tee) joints. Fibrex provided it’s proprietary process smooth-turn joint with 1” and 1 ½” radius on each branch connection. This radius provides smoother flow reducing turbulence, erosion and horsepower requirements.